- Description

- Technical data

- Features

The key to success in bridging the gap from the laboratory to commercial production is a pilot plant that delivers results that will be relevant when you move into full-scale production. Scaling-up involves compromises that often cannot be predicted in the laboratory.

Alfa Laval solves this problem with the versatile BTPX 305 centrifuge. Suitable for feedrates up to 2 000 litres per hour, the BTPX 305 can be delivered in a multitude of configurations and it is therefore adaptable to almost any duty and application imaginable.

For hazardous duties the centrifuge complies with ATEX requirements for zone 1 or 2 and a skid mounted separation system can be designed for inert gas purging, thus insuring the highest level of safety. For biological hazards the separation system can be designed for steam sterilization and contained operation, which meets the requirements of the NIH guidelines for BLS 2.

Applications:

The BTPX 305 is a solids-ejecting centrifuge in clarifier, purifier and concentrator execution, equipped with a well-proven, reliable fixed partial solids discharge, which can be initiated by timer, turbidity and/or totalized flowrate.

In the clarifier execution the centrifuge is used for removing suspended solids from a liquid, while in the purifier and concentrator execution it is used for removing suspended solids, while separating two intermixed and immiscible liquid phases of different densities.

The solids content in the feed is normally in the range of 0.1–10% by volume, but can vary between different duties.

The BTPX 305 separator is available in various surface polishing options:

| Bowl spindle |

Ra 0.8. Ra 0,5 and electro polished. |

| Machine top part |

Inside Ra 1.2. Outlet cover Ra 0.5 and electro polished. |

| Machine top part |

Inside Ra 0.8. Outlet cover Ra 0.8. |

| Machine top part |

Inside Ra 0.8. Outlet cover Ra 1.2. |

| Separator bowl |

Inside 0.5 Ra and electro polished. Outside 0.8 Ra. |

| Separator bowl |

Inside 0.8 Ra, outside 0.8 Ra. |

| Separator bowl |

Inside 1.2 Ra, outside 1.2 Ra |

Technical data

| Hydraulic capacity |

3 m3/h* |

| G-force, max |

12,800 |

| Bowl speed |

6,000-9,650 rpm |

| Installed motor power, control torque |

7.5 kW |

| Main power supply |

3x400x50 Hz |

| Noise level |

77 dB(A) |

* Actual capacity depends on feed material and separation demands.

Utilities consumption

| Electric power, max |

7.6 kW** |

| Operating water |

0.2-0.35 L per discharge |

| Flushing above/under the bowl |

up to 10 L per discharge |

**Depends on feed flow rate.

Shipping data (approximate)

|

Centrifuge |

Complete system |

| Net weight |

450 kg |

1,400 kg |

| Gross weight |

600 kg |

1,760 kg |

| Volume |

1.0 m3 |

12 m3 |

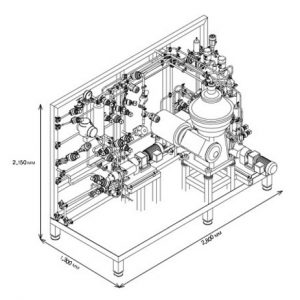

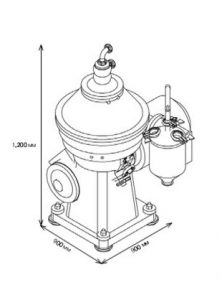

Main dimensions (approximate)***

|

Centrifuge |

Complete system |

| Height |

1,200 mm |

2,150 mm |

| Width |

900 mm |

2,800 mm |

| Depth |

900 mm |

1,300 mm |

***Can vary according to specific demands.

Material data

| Bowl body, hood and lock ring |

Stainless steel 1.4462 UNS S31803 |

| Solids cover and frame hood |

Stainless steel ASME SA-240 S31603 |

| Cyclone |

Stainless steel ASME SA-240 S31603 |

| Bottom frame |

Cast grey iron |

| Inlet and outlet |

Stainless steel, mostly 1.4401 UNS 31600 |

| Gaskets and O-rings |

EPDM rubber (FDA approved food grade), viton or nitrile |

The machine consists of a frame that has a horizontal drive shaft, worm gear, lubricating oil bath and a vertical bowl spindle in the lower part. The bowl is mounted on top of the spindle, inside the space (bowl casing) formed by the upper part of the frame, the solids collecting cover and the frame hood.

The bowl casing is double-walled for cooling and noise reduction. There is a mechanical seal at the top of the spindle to make sterilization with steam possible. For continuous pressurized discharge of separated solids the machine is fitted with a non-rotating device, a paring tube, positioned inside a central chamber, to which the separated solids flows through vortex nozzles.

All metal parts in contact with the process liquid are made of stainless steel. For CIP, the bowl contains an automated hydraulic operating system or discharging. It is a system, in which the bowl content is emptied in connection with an automated CIP procedure. The discharge takes place at full speed without any interruption of feed of CIP liquids.

The centrifuge is available with main connections as sanitary clamps and all other utility connections of clamp type. The electric motor is suitable for variable frequency drive, which makes it possible to have bowl speeds down to 62% of the maximum bowl speed.

The design conforms to a number of EC directives, and the machine is made in accordance with the general directives for machinery. The machine is equipped with nozzles for flushing of the bowl top, the bowl bottom and the solids collecting chute.