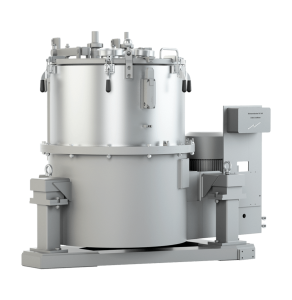

Technical Centrifuge for various applications like filtering, separating, washing, drying, clarifying, rinsing, impregnating and pickling.

Large-capacity basket centrifuges are used where higher amounts of solids are encountered. What gravity does naturally, CEPA centrifuges accomplish many times faster and more effectively. Not only can suspensions be separated efficiently; parts can also be spin-dried. This is done using inserts developed to reflect the customer’s requirements.

CEPA TZ 3/TZ 4 is a batch-operating, top discharge centrifuge for various applications. Filtration as well as decantation processes are possible depending on the drum. Removable cover ring and the fixed filter bag make an efficient collection of the product possible.

Centrifuge with central bearing for lateral drive by V-belt, with AC motor and perforated drum, completely mounted on a triangular frame, carried on swinging elements, sealings at the middle bearing and at the machine housing made of Perbunan, casing made of stainless steel 1.4571, with discharge socket G 2", cover also made of stainless steel 1.4571, collecting tube is lined with stainless steel sheet 1.4571, with cover locking device, all surfaces coming into touch with the product as well as lid and housing smoothened surface finish Ra=1.0;

With perforated drum made of stainless steel 1.4571, with firm drum board and put in filter bag, diameter 300 mm, clear height 200 mm, perforation of the drum 3 mm diameter, max. charging weight 20 kg resp. 10 litres, max. drum speed 1850 rpm.;

With AC centrifuge motor, three-phase, with brake 400 VDC;

With control desk for installation next to the centrifuge, with all switchgears necessary for the control of the centrifuge;

Connected load: 400V, 50Hz, approx. 4kW.

| Model |

CEPA TZ 3 |

CEPA TZ 4 |

CEPA TZ 5 |

| Drum diameter (mm) |

300 |

400 |

500 |

| Revolution (rpm) |

2450 |

2110 |

1.900 |

| G-force max. |

1.000 |

980 |

1000 |

| Rotor volume, l |

10 |

20 |

35 |

| Filling amount (kg) |

20 |

30 |

50 |