- Description

- Technical data

- Features

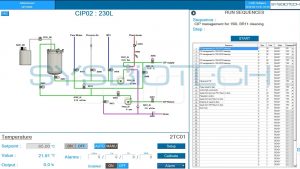

SYSBIOTECH engineering unit developed a fully automated stationary CIP-station for (bio)reactors, vessels and piping, which is currently available in standard version with tanks’ working volumes of 2×500 L.

Constructive design and reliability of our CIP-station not only ensures production of safe and quality products and increases their shelf life, but also reduces the costs of monitoring procedures for technological processes and products, increases the effectiveness of quality management systems, eliminating the need for operations to dismantle the removable parts and make connections in clean rooms.

Standard platform design (skid) allows for SIP/CIP functions for fermenters, bioreactors, piping or vessels with volumes from 2,000L up to 5,000L (depends on working volume of CIP tanks and configuration of processed vessel).

New C-BIO2™ operator and control platform provides enhanced functionality and process control options as well as full integration and connectivity to SYSBIOTECH’s Process Line equipment and third party (equipment) supervisory software, making it the ideal platform for the automation and data integration of your cleaning/sterilization process.

The CIP-station consists of two tanks, a steam heat exchanger, two centrifugal pumps (supply and return), control and measuring equipment (temperature, pressure and conductivity sensors) and control unit.

Control cabinet

The control unit is installed on the frame. External dimensions for a box controller: 760х760х300 mm. Touchscreen PC and trackball keyboard are installed for comfortable operator work.

Components

Power supply, switches, fuse and frequency converters for the drives.

Measurement systems

Optimized PID measurement system and transmitters to control the following functions:

- Temperature: measurement, control and recording

- Conductivity: measurement, control and recording

- Pump speed: measurement, control and recording

- Pressure: measurement, control and recording

- pH: measurement, control and recording

Automation:

- Touchscreen 15”, industrial computer with Phoenix PLC for control process including specialized software

- Windows XP Professional operating system

CIP-station is equipped with pumps, heat exchangers, valves, sensors from leading manufacturers.

The station is equipped with an automatic system for maintaining and changing the pH of cleaning solutions to optimize the washing process and configuration of technological processes.

| Technical description |

| Working pressure of water |

Up to 3 bar |

| Working pressure of WFI |

Up to 3 bar |

| Working air pressure for blowing |

Up to 2,5 bar |

| Working pressure instrumental air |

5-7 bar |

| Steam working pressure |

Up to 2.5 bar |

| Working pressure water drain |

Without pressure |

| Max temperature |

+85°C |

| Material that contact with the product |

AISI 316L |

The standard platform design further includes a comprehensive range of options including but not limited to on-board supply and monitoring of heating, cooling, fluid mixing, pumping and steam supply, and more.

For application-specific functionality or for higher volume SIP/CIP our engineering department is happy to support you with configuring the system that satisfies your needs.

SYSBIOTECH’s constructive and flexible design, choice of quality materials and reliable operational functionality ensures a long equipment life cycle for the manufacturing of safe and high-quality products. The use of C-BIO2™ software enhances automation and minimizes the need for human monitoring, thereby reducing overall cost and increasing the effectiveness of quality management systems.

Each system is fully tested in-house (FAT).Tests after on-site assembly and commissioning (SAT), and training of your personnel are included.